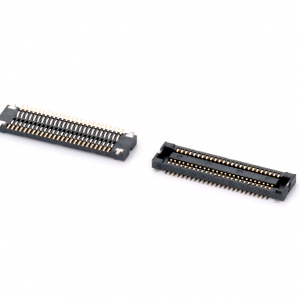

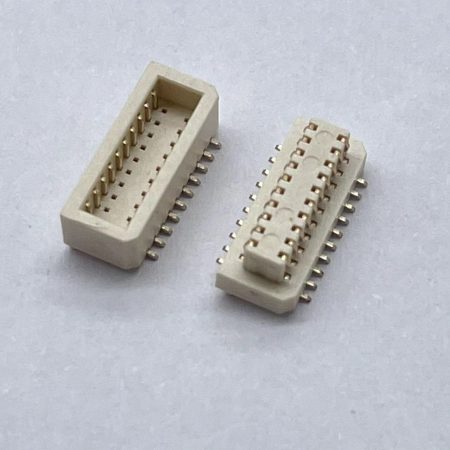

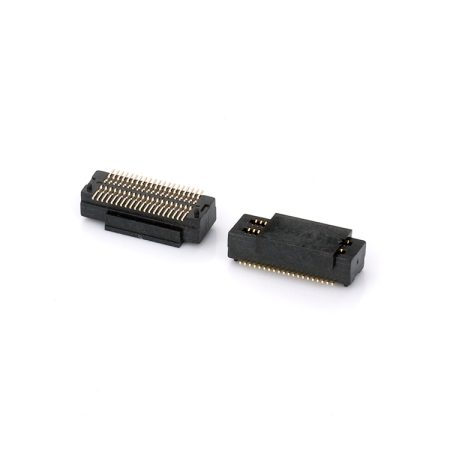

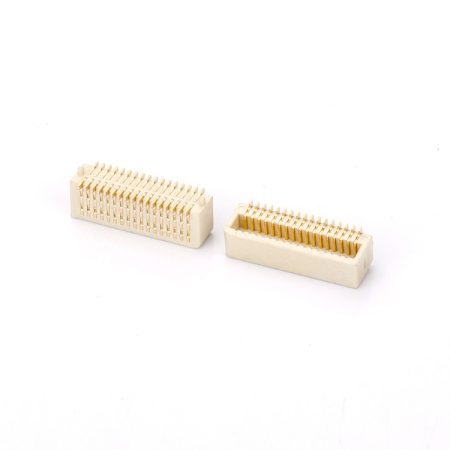

Board-to-board connectors for consumer electronics, communication networks, industrial electronics, automotive electronics, aerospace and defense, medical equipment, data storage…

Board-to-board connectors are essential components in electronic design and manufacturing, enabling the seamless integration and interconnection of multiple PCBs or electronic modules, leading to the development of complex and multifunctional electronic systems. Widely used in consumer electronics, communication networks, industrial electronics, automotive electronics, aerospace and defense, medical equipment, data storage…

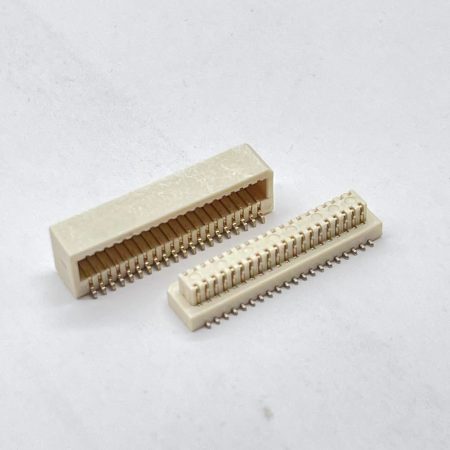

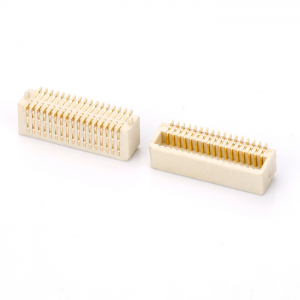

The board-to-board connectors are versatile and can facilitate various types of connections, including power transmission, signal routing, and data transfer between PCBs. With the advantages of easy assembly, modularity, high-density interconnects, and mechanical stability. Its common spacing covers 0.4mm, 0.5mm, 0.635mm, 0.8mm, 1.00m, and 1.27mm, customized spacing is also available from LWX Connectors.